BALANCING SERVICES

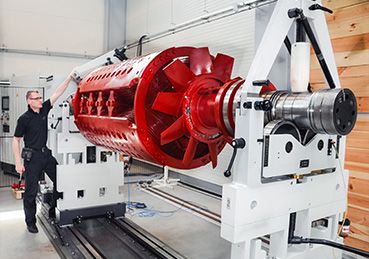

Our Balancing Center is one of the dozens of facilities in the world that offers professional balancing services quickly and competently. The greatest advantage of these facilities is that services are provided by experienced specialists in the field of balancing and are performed on the latest SCHENCK balancing machines.

From individual components and prototypes to mass production - in our Balancing Center we offer balancing services for all rotors, including but not limited to: electric motor rotors, fans, spindles, turbines, pulleys, gears, flywheels, crankshafts, pump rotors, rotating components, rollers, tools, brake discs, crusher rotors, paper shafts, agitators, generators and more.

We balance rotors and drive units both on stationary balancing machines and at the customer's site using portable equipment. We also carry out vibration diagnostics.

Rotor range from 10 grams to 25 tons.

Our offer:

- balancing individual rotors and balancing in series

- high speed balancing

- balancing tool holders and tools

- precise balancing in balancing up to even G 0.4

- field balancing and vibration diagnostics at the customer's plant

- overspeeding and spin tests

OUR MACHINES

We provide balancing services on the latest SCHENCK machines, including:

HM60U universal horizontal balancing machine (up to 25t, 9m length, 3m diameter), HE40BU universal horizontal balancing machine (up to 3000kg), HE3BU universal horizontal balancing machine (up to 300kg), HE1BK universal horizontal balancing machine (up to 10kg), universal vertical balancing machine Virio 100 (up to 100kg), Tooldyne vertical balancing machine for tools and toolholders, Pasio 05 horizontal balancing machine for rotors up to 500g, TBsonio and TBcomfort for balancing turbocharger components, and SmartBalancer v3 for field balancing and vibration diagnostics.

Technical data of rotors that we can balance in our Balancing Center:

- maximum diameter 3,000 mm

- maximum length 9,000 mm

- maximum weight 25,000 kg

- maximum balancing speed 250,000 rpm

In inquiries, please send drawings or photos and provide the following rotor data necessary to prepare the quotation: weight, length, diameters, method and place of correction, type of rotor, nominal working speed.

Quotations are prepared individually - contact: Ten adres pocztowy jest chroniony przed spamowaniem. Aby go zobaczyć, konieczne jest włączenie w przeglądarce obsługi JavaScript. | Phone: +48 32 788 8285 / Phone: +48 32 788 8283

©RoTec Polska 2022. Wszystkie prawa zastrzeżone.

©RoTec Polska 2022. Wszystkie prawa zastrzeżone.