DRY ICE BLASTING MACHINES

CRYONOMIC has been offering innovative dry ice blasting solutions for over 25 years. Thanks to patented dry ice feeding technology, CRYONOMIC machines provide the highest dry ice blasting pressure available while using less dry ice than competitive machines.

How does dry ice blasting equipment work?

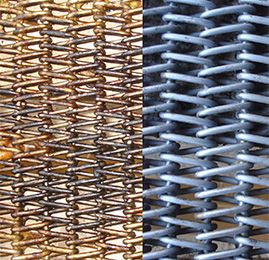

Dry ice blasting is a non-abrasive, high-pressure blast cleaning technique. The advantage of using solid CO2 or dry ice pellets as a cleaning material is twofold. First, very low temperature of dry ice pellets causes the contaminants to freeze and shrink, making them easier to separate from the substrate. Secondly, dry ice pellets, made of carbon dioxide gas, evaporate, which means that only original contamination is removed. Natural evaporation process of dry ice pellets is the main advantage of dry ice blasting method. Dry ice is a solid form of CO² with a temperature of -79° C. It is called dry ice because it does not contain water and simply evaporates at room conditions. Pellets with a diameter of 3 mm are used for cleaning.

Why dry ice blasting?

Cleaning by well-known traditional methods in an industrial environment poses many problems. Cleaning methods like sandblasting, solvent cleaning, high pressure cleaning or manual cleaning are often too aggressive, causing damage to the surface to be cleaned, or they pose a threat or pollute the environment. The CRYONOMIC® dry ice blasting method has been developed as an effective, fast and environmentally friendly alternative method for cleaning almost any material in a wide variety of environments.

Benefits of dry ice blasting:

- in many cases, it reduces equipment downtime because it does not need to be dismantled and can be cleaned in its on site

- it eliminates the need to use detergents and chemicals for degreasing

- it does not damage the surface, unlike sandblasting, glass blasting or mechanical cleaning

- it is environmentally friendly - removes difficult contaminations without by-products (dry ice simply evaporates)

- compact and versatile solution - the device can be used to clean large objects and components on site

- dry ice blasting can be performed anywhere where it is not possible to use water, sand or other products, e.g. in live machines or in the food industry

CRYONOMIC® dry ice blasting equipment

These machines are distinguished by their reliability and excellent work ergonomics. There are two basic series of dry ice blasting machines - COB and COMBI 7. The COB series are devices working with one hose that feeds air together with dry ice. COB 62 (smaller machine and lower pressure) and COB 71 (larger machine and higher pressure) versions are available. The COMBI 7 series, thanks to the supply of air and dry ice through separate hoses, offers a significantly higher cleaning capacity and pressure up to 16 bar. The devices are equipped with a wide range of accessories - guns and nozzles for cleaning all types of surfaces and dirt. Optionally, the device can be equipped with a module for even stronger cleaning with a small addition of abrasive medium (eg. sand), which allows to remove very stubborn contaminations. CRYONOMIC machines are virtually maintenance free, very easy to use and optionally allow remote control of the cleaning functions from the gun.

Main applications of dry ice blasting technology:

- cleaning of machines and devices (also in motion)

- cleaning of printing equipment, rollers, dies, etc.

- cleaning of production lines without dismantling

- renovation of monuments, old cars and machines

- cleaning of welding robots and various types of equipment

- injection mold cleaning

- cleaning the elements of electric and internal combustion engines

- cleaning of machine control cabinets

- removing the effects of fires in buildings

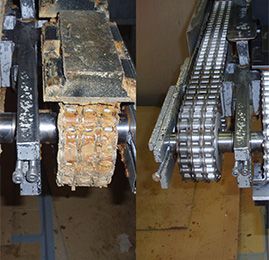

- cleaning mechanisms, gears, chains, guides

- removal of graffiti, paints and varnishes

- cleaning of belts, ovens, baking trolleys in the food industry

CRYONOMIC® dry ice production machines

We also offer machines for production of dry ice, the so-called pelletizers. They allow for reliable, efficient and economical production of dry ice pellets with a diameter of 3, 10 or 16 mm with a capacity of 35 to 300 kg/h. We also offer high-quality dry ice storage containers.

CRYONOMIC dry ice cleaning blasters

Renovation of buildings, monuments, removing graffiti, restoration after fires

Food industry – cleaning of lines, machines, tanks, molds

Power industry - cleaning of turbines, generators, motors, control cabinets

Metal machining - removing of rust, deburring after laser cutting, cleaning after welding

Chemical industry - cleaning of tanks, pharmaceutical molds, production equipment

Printing and paper industry - cleaning of printing rolls and machines

Removing remains of plastic and rubber from molds and production machines

Automotive, railway and airlines industry - cleaning of engines and other parts, molds, removing paint, cleaning railway cars and drive components

Error

For more information, please check www.cryonomic.pl . If you need any support, do not hesitate to contact us.

©RoTec Polska 2022. Wszystkie prawa zastrzeżone.

©RoTec Polska 2022. Wszystkie prawa zastrzeżone.