ULTRASONIC CLEANING TECHNOLOGY

Ultrasound working principle

Ultrasounds are sound waves with a frequency of 20-100 kHz. In the cleaning process, sound waves cause microscopic gas bubbles to expand and contract until they implode, creating a cavitation phenomenon and releasing huge amounts of energy. The result is a mechanical cleaning process similar to microbrushing or shot blasting at a very high frequency (28 000 times per second). Cavitation at the frequency of 28 kHz, at which Ultratecno machines work, involves the formation and implosion of larger air bubbles, thus releasing more energy and increasing the cleaning effect, resulting in better efficiency and shorter cycle times.

Co wyróżnia myjki Ultratecno?

UltraTecno 28 kHz ultrasonic transducers

Our transducers are made of high-quality phosphor-bronze/silver materials and are designed to minimize heat build-up, thereby extending their lifespan. Placing the transducers in the walls of the machine guarantees constant, high quality of cleaning throughout the entire time of use, avoiding the negative impact of contaminants accumulating on the bottom.

Synchronized generators

Digital synchronization of UltraTecno generators ensures that all ultrasonic transducers are in the same phase, avoiding pressure wave absorption and increasing the cavitation effect.

Our electronic generators include up to eight frequency sweep modes designed to enhance performance of the transducers, plus additional Stop&Go function.

Triple thermal insulation

Our machines are fully insulated with triple-thickness material - up to 50 mm. The top lid is also insulated and the neoprene seal prevents steam leaks. Our thermal insulation system reduces heat loss by 72%, making it the most efficient on the market.

Acoustic Reduction Filter (ARF)®

28 kHz is the most efficient and desirable frequency for cleaning heavily contaminated parts and components but it is also the loudest. UltraTecno engineers have developed the patented ARF technology, which, using acoustic filters and special insulation, keeps the noise level below 78 dB (A). You can now enjoy full power of ultrasonic cleaning at 28 kHz with no excessive noise.

Oil Separation System (LFS)®

After removing the oil and grease from the parts, they must be separated from the main water tank. Our patented LFS technology collects floating lubricants into an auxiliary tank where they can be easily removed by the user, keeping all components perfectly clean when removed from the unit.

Loading platform

Ultratecno industrial ultrasonic cleaners are equipped with a pneumatically lifted platform. It allows for much better cleaning results and facilitates work, making loading and unloading parts from the machine much more convenient.

APPLICATION

Automotive industry

Ultratecno cleaning machine series for the automotive industry has been specially designed for cleaning and degreasing every element and type of contamination in this industry.

It achieves very good results in the case of many materials and complex parts providing lowest energy consumption and highest efficiency.

Ultratecno cleaning machines use ultrasounds with frequency of 28 kHz, which provides the best results for this type of contamination. Higher frequencies (from 40kHz) have a weaker effect and are used for other applications with less contamination and more delicate materials.

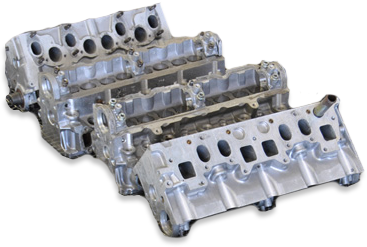

Ultrasonic cleaning of automotive engine components offers many benefits, both in terms of quality and economy.

Ultratecno ultrasonic cleaners ensure the highest quality of cleaning engine heads, cylinders, pistons, engine blocks, manifolds, carburettors or injectors, as well as cleaning turbochargers, diesel particulate filters (DPF), fuel pumps, catalytic converters and gears.

The ACM series industrial cleaning machines have a pneumatically lifted platform that greatly facilitates work and helps load the parts, and at the same time, thanks to the continuous agitation movement during cleaning, it strengthens the effect.

Marine engines repairs

UltraTecno ultrasonic cleaning machines are the best solution for plants repairing ships, marine engines and other components.

Our large cleaning tanks made according to the customer's needs are the most advantageous and proven solution - for over 20 years, UltraTecno has been a world leader with over 80% market share.

Our industrial ultrasonic cleaning machines are particularly suitable for cleaning large cylinder heads, injectors, pistons, exchangers, turbochargers and all other mechanical components.

UltraTecno provides specialized equipment for cleaning engine components of ships and other units. For this we use the highest quality components and technology, which we have refined over many years in cooperation with our customers. These are large cleaning tanks with a capacity of several to several thousand liters, with appropriately adjusted ultrasound power and equipment for effective and economical cleaning of ship engine components during their repairs and overhaul.

Cleaning of printing rollers

It doesn't matter which printing system you use - UltraTecno machines ensure the highest quality of washing anilox rolls, printing rollers and other elements of printing machines.

Our washers have a special system for rotating rollers and are designed for specific products and customer requirements, which allows you to obtain the highest quality of cleaning, and thus, your final product.

Injection mold cleaning

UltraTecno industrial ultrasonic cleaning machines completely remove all substances and materials remaining on injection molds, such as any type of burnt plastic or rubber.

Our solutions ensure excellent mold surface quality and no contaminants that could deteriorate product quality. High cleaning standards ensure faster response times and the start of production of the next batch immediately after mold installation.

Multi-tank systems

UltraTecno company also specializes in the supply of multi-tank cleaning machines for various industrial cleaning processes, such as removing polishing paste, degreasing or removing chips after machining or stamping.

UltraTecno multi-chamber cleaners can be equipped with the following processes:

- standard ultrasonic cleaning with the movement of the platform on which the parts are located

- one or several stages of rinsing, with the possibility of filtration with activated carbon or with the use of demineralized water

- protection against corrosion using passivation baths or oil

- hot air drying

In addition to standard models, we also make special cleaning machines, designed in accordance with customer requirements. Please contact us for a quote for a suitable solution.

STANDARD MODELS

| Model | Capacity (litres) | Lift max. load | Ultrasounds (kW) | Heating power (kW) | Internal tankdimensions (mm) | Loading tray (mm) | Automatic top lid |

|---|---|---|---|---|---|---|---|

| ACM-100E | 110l | 50kg | 1 kW | 3,75 kW | 600 x 400 x 470 | 550 x 320 | Optional |

| ACM-200E | 200l | 75kg | 2 kW | 7,5 kW | 800 x 500 x 500 | 750 x 420 | Optional |

| ACM-350N | 400l | 250kg | 3 kW | 7,5 kW | 1000 x 670 x 730 | 950 x 527 | Optional |

| ACM-500N | 587l | 350kg | 4 kW | 11 kW | 1200 x 670 x 730 | 1090 x 544 | Optional |

| ACM-750N | 840l | 500kg | 5 kW | 11 kW | 1400 x 800 x 750 | 1280 x 670 | Optional |

| ACM-1000N | 1224l | 800kg | 7 kW | 18 kW | 1600 x 900 x 850 | 1480 x 760 | Yes |

| ACM-2000N | 2178l | 1000kg | 9 kW | 27 kW | 1800 x 1100 x 1100 | 1750 x 900 | Yes |

| ACM-3000N | 3276l | 1000kg | 12 kW | 27 kW | 2100 x 1300 x 1200 | 2050 x 1110 | Yes |

| ACM-4500N | 4846l | 1800kg | 15 kW | 36 kW | 2400 x 1590 x 1270 | 2350 x 1400 | Yes |

| ACM-5500N | 6010l | 1800kg | 18 kW | 45 kW | 2700 x 1590 x 1400 | 2650 x 1400 | Yes |

©RoTec Polska 2022. Wszystkie prawa zastrzeżone.

©RoTec Polska 2022. Wszystkie prawa zastrzeżone.